4130 Chromoly Tubing- How to TIG weld 4130 Chrome Moly

scroll down for the best videos on tig welding 4130 chromoly tubing

- HOME

- Tig Welding 4130

- 4130 Chromoly Tubing

...Introducing the New WeldMonger Challenger TIG kit that includes the most frequently used Cups.

more videos on tig welding 4130

return to main tig welding videos

4130 Chromoly tubing is mostly Iron but has additions of Chromium and Molybdenum that along with a .3% carbon content, makes for a heat treatable low alloy steel that is much stronger than mild steel tubing.

4130 tubing is used extensively in the motorsports industry for monster trucks and trophy trucks as well as for various types of chassis, roll cages, etc.

41XX category of steels are referred to as chromoly steels because of the alloying additions of chromium and molybdenum.

4130 is one of the most common 41XX steels but there are several others like 4140, 4145, and 4150 to name a few.

(see this wikipedia page on 41XX steels)

4130 tubing is often referred to as "aircraft tubing" but is used for all sorts of other items like bicycles, motorcycles, and motorsports applications.

The "30" in 4130 indicates a 0.3% carbon content.

But some carbon equivalent formulas calculate the carbon equivalent at around .44%

a carbon equivalent of .44% means that 4130 tubing has the potential to harden if it cools too quickly during the welding process.

Especially if 4130 filler metal is used as a tig filler metal.

That is why ER70s-2 is a better choice for tig welding 4130 chromoly tubing because it is less crack sensitive and provides a more ductile weld than 4130 filler metal does while still providing adequate strength.

ER80s-D2 is also a good choice and sometimes flows a little better than the er70s-2 rod.

And the studies and results of lots of research are in. 4130 chromoly can be welded without a preheat or post heat if it is less than .120" thick.

But a quick preheat wont hurt.

For this video on this page, I chose ER80s-D2 simply because I wanted .045" diameter and that is what I had.

learn more about this CK tig welder

click here to learn more about the Furick ceramic 12 cup

Clean the mill scale.

4130 tubing usually comes with a very light mill scale.

yes 4130 tubing can be tig welded without cleaning, but it is not any fun and the welds just dont look as nice.

I used a flap disc but there are special abrasives designed to remove light mill scale without removing wall thickness.

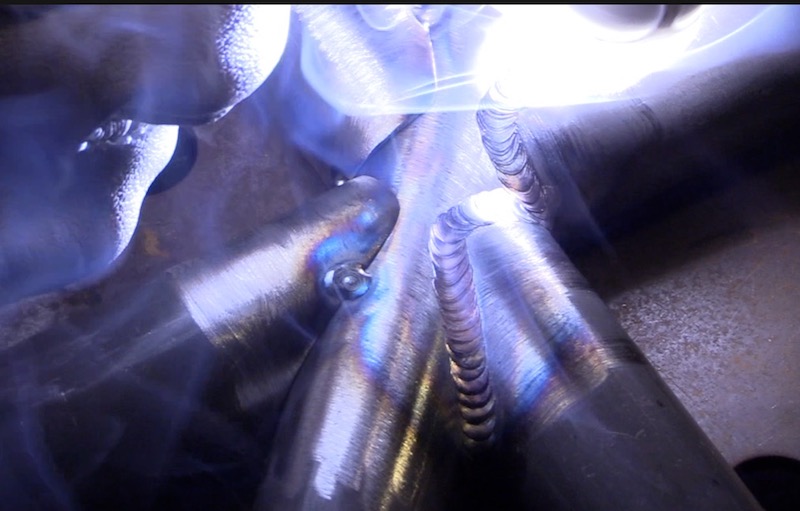

After making several small tack welds, I welded one side at a time and let cool after each run.

I found that using the Furick Ceramic 12 cup. I was able to utilize a 3/4" stickout and easily reach the tight throats of each joint.

Welding Procedure Used for this 4130 chromoly tubing cluster

- Base Material Type/Thickness - 1" 4130 chromoly tubing .063" wall thickness

- Prep Method - flap disc to remove mill scale followed by acetone wipe

- Filler Metal Type/Size - ER80S-D2 .045"

- Tungsten size and prep - 3/32" 2% lanthanated sharpened to 30%

- Gas Type and Flow Rate- argon 25-30cfh

- Cup size - Furick Ceramic 12 (available at weldmonger.com)

- Current/Polarity - DCEN 65 amps

- Length of Arc - equal or less than 3/32"

- Angle of Travel - usually 15% but angle changes on cluster joints

- Manipulation/Technique - dip, travel, pause

- Speed of Travel - 4-5 inches per minute