Socket Welds using both "walking the cup" and "freehand" techniques

If you were searching for tips on "Tig Welding Socket welds" you are in the right place.

This video shows both "walking the cup” and "freehand" techniques for Tig welding carbon steel sockets.

here are 2 other videos about socket welds

making a chinup bar using socket welds

Socket

welds are part of the gig if you are a pipe welder….Not the most

challenging welds there are ...But not something you typically get any training on

when you are in welding school either.

So the main reason for

this video is to provide a training tool for new pipe welders fresh out

of school, or for plant maintenance personnel too who might be required

to make a socket-weld every now and then....or anyone else who might

benefit from watching.

Many years ago, in welding school, we did 2g, 5g, and 6g pipe….all geared toward helping us pass a 6g welding test.

And codes being what they are, when you pass the 6g butt weld test, you are automatically qualified to weld socket-welded joints…I guess thats why I never touched a socket-weld pipe joint until I was in the field for about a year.

…and the first job I where I had to do sockets was on a paper mill where the stainless socket-welds were tig welded but all the carbon steel socket joints were stick welded.

On that paper mill job, most socketwelds were not even inspected. An inspector would show up occasionally and spot check welds, but most of them were not inspected at all to my knowledge.

But on my first nuclear plant, things were very different.

On all the nuclear jobs I worked, Socketwelds were done using a WPS (welding procedure specification) where amperage range was listed along with minimum weld size that was checked by a CWI ( certified welding inspector) using a fillet weld gauge.

It was surprising just how much weld was required on some of those heavy wall schedule 160 socket welds...several passes were needed to achieve the minimum fillet size.

and all the socketwelds I did on nuclear jobs were tig welded….and were required to have a specific gap prior to welding.

Welding practices on a paper mill can be very different from a nuclear job.

But the point is this… Socket welds are used quite a lot for piping on submarines, ships, power plants, chemical plants, and paper mills, and factories…especially for 2” dia pipe and smaller.

The main reason is cost.

Can you imagine how much longer it would take to run several hundred feet of 1" stainless steel pipe butt welds vs socket welds?

a good example is stainless pipe, no purge is needed. vs butt weld fittings where a purge is needed even for tack welds.

with butt welds, you need alignment tools, tack welds need to be purged as well as feathered, ends need proper bevel and cleaning is required on both inside and outside diameter.

its just a lot quicker and easier to install pipe using socket fittings than it is using butt weld fittings.

and there is no issue of mismatch with socketweld fittings. ( aka “high low”).

And there is almost no prep work required except for removing mill scale coating from carbon steel pipe and fittings.

now ...all that said, there have been quite a lot of socket weld failures in power plants in service....

Certain High stress applications that undergo vibration, thermal cycles, and expansion and contraction sometimes need more flex and fatigue resistance than socket fittings can provide.

at least that seems to be the consensus from the failure reports.

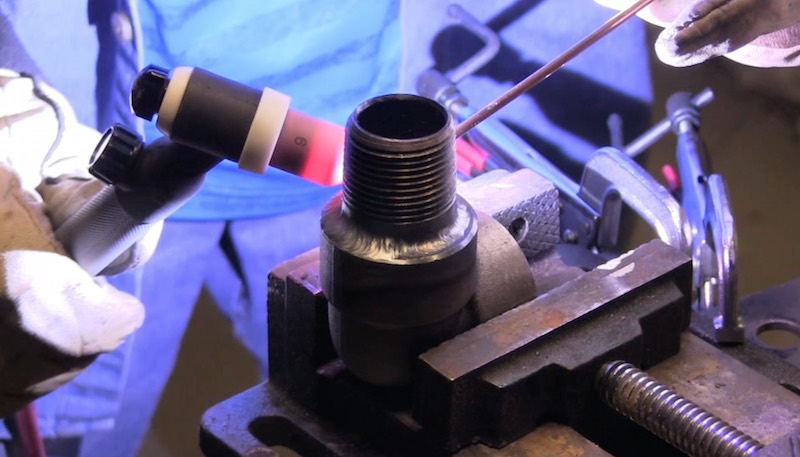

Techniques for socket welds…walking the cup vs freehand.

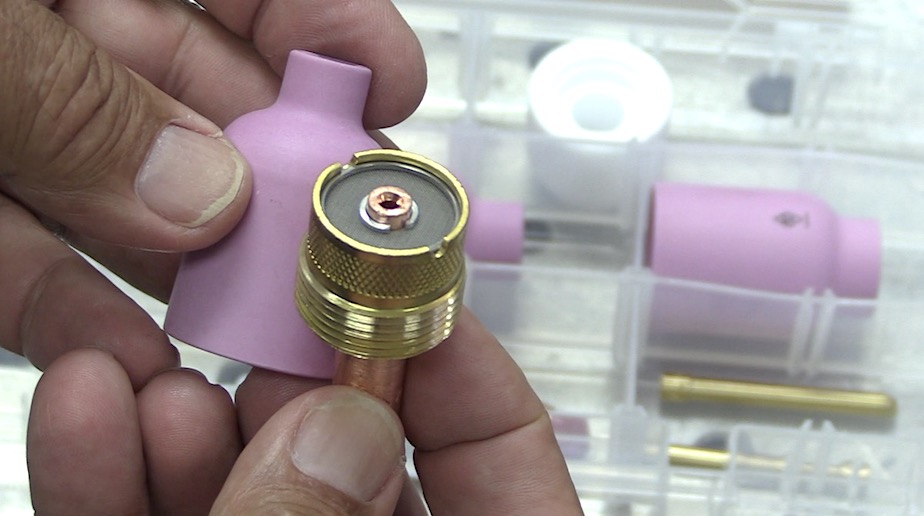

Our new LArge Diameter Gas lens kit now comes with 5/32" setup for those high amperage jobs

Walking the cup is a great technique for socket welds.

Its

fast, and efficient, and keeps your hand away from the heat…and with a

tripod vise, a welder can walk around the joint and not stop until done

and that is usually a good thing.

But sometimes in the field, there is stuff in the way...like other pipes...and freehanding is the only choice.

Why 2 passes for socket welds?

Codes like Asme

ANSI B31 often require that more than a single pass is done for socket

welds. Probably just becasuse there is much less risk of a leak ..and

also to prevent excess heat input and grain growth.

So for these

welds in the video, I used 2 passes…one using a 3/32”( 2.4mm) filler

rod..and the second pass using a 1/8” (3.2mm) filler rod.

The Lincoln power mig 210 mp is foot pedal capable but does not come that way. ( at least not at the time I wrote this) .

But

it is pretty easy to just hook it up just like you would a scratch

start tig rig using an adapter (105z57) that cost less than 20 bucks.

( works for 9 and 17 size air cooled torches...sometimes a 26 requires a different adapter)

So that is what I did. and then just clamped the stick electrode holder onto that.

When you use the 105Z57 adapter to hook up the torch like a scratch start rig, you need a tig torch with a valve…and you need to remember to

turn the valve on before you strike an arc..and then you need to

remember to turn it off once you finish a weld to avoid wasting your

argon gas.

oh and remember...Socket-welds are sometimes stick welded.

coming soon, …video on stick welding socket-welds using the lincoln power mig 210mp.

here are 2 other videos about socket welds

making a chinup bar using socket welds